News

Modern methods of construction: The key to safer healthcare scheme delivery

6 Oct 2022

Ensuring a smooth delivery on site for any scheme is important, but especially so when working within a live environment. Those live sites with arguably the highest level of sensitivity to any potential issues from development are healthcare environments, so removing this risk must inform the way in which we tackle such projects. Project manager Joshua Sandbach discusses how modern methods of construction can hold the key to minimising any disruption to staff and patients in such an environment.

Modern methods of construction (MMC) refers to the ways in which we can build more quickly, reliably, safely, and sustainably, with the various methods continuing to grow in popularity as the benefits become more widely understood.

Last month, the Cabinet Office published its first update to the Construction Playbook with a 22-page guidance note that further promotes the use of offsite, prefabrication, and modular platform approaches for public sector clients. This shows the emphasis across the board on these modern, innovative methods is continuing to grow, and we expect to see them forming part of more and more client briefs into the future.

Two of the most prominent and obvious benefits to using MMC on built environment schemes are reduced live site time and the associated reduction in potential safety issues. These alone are reason enough to understand why these tactics are forming part of more and more briefs. However, it is even clearer to see why when we examine them in relation to healthcare settings, especially when combined with a phased approach to development.

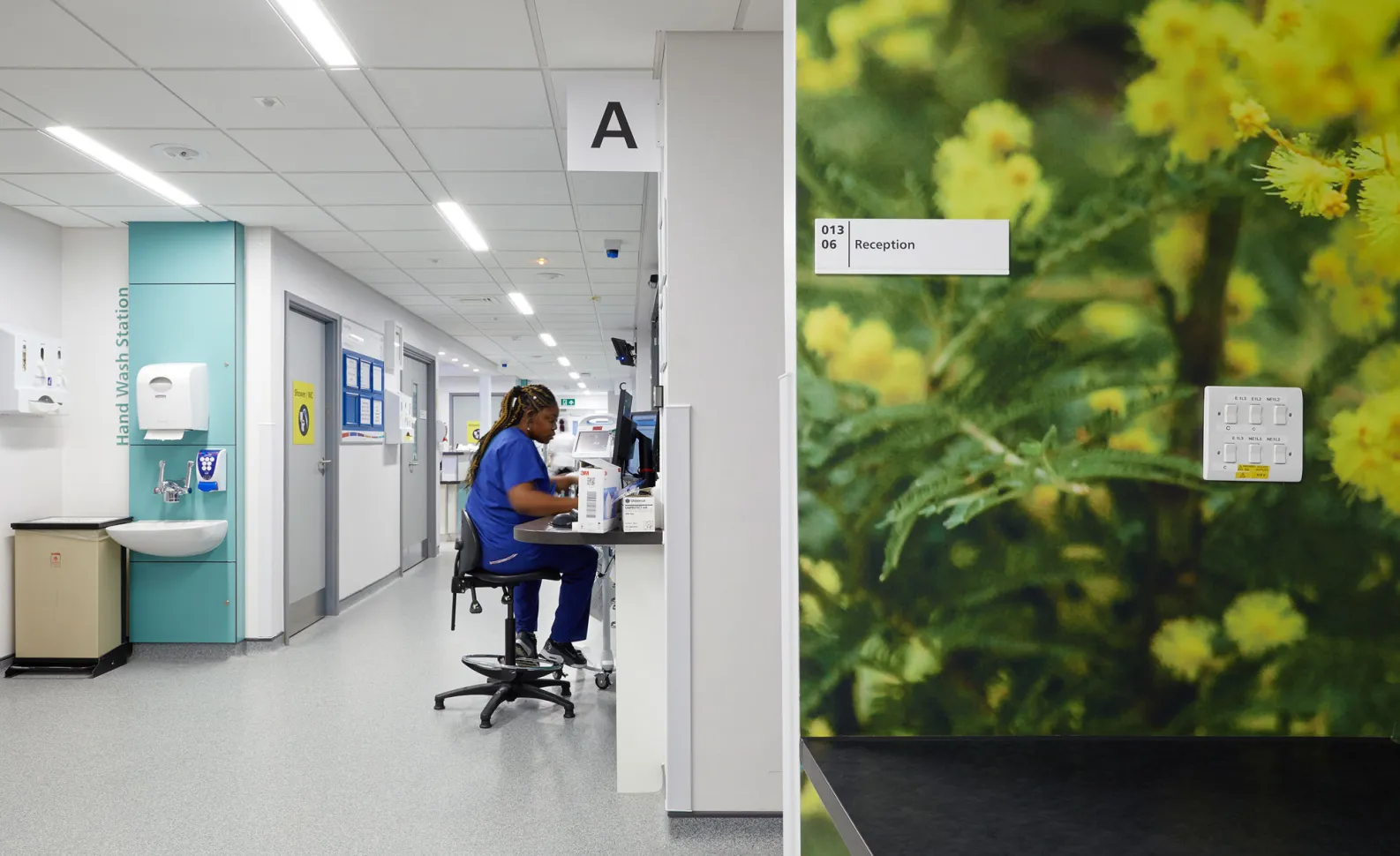

A prominent healthcare scheme that utilised modular construction as a solution for the challenges of delivery in a live site was our work to relocate children’s congenital heart services from Glenfield Hospital to Leicester Children’s Hospital within Leicester Royal Infirmary. Due to its scale and many moving parts, this work would ultimately be delivered in three key phases.

The central and largest part of this scheme was the existing Kensington Building, which formed the first phase of work once the existing maternity department and gynaecology assessment services were relocated. This stage incorporated refurbishment and a three-storey new-build extension to house the new cardiac outpatients’ department, cardiac theatre, and hybrid catheter lab.

With the extension structure being designed to achieve BREEAM ‘Very Good’, a significant number of measures to minimise energy consumption during the normal operation of the building were also incorporated within the overall design development strategy, thereby embedding a more sustainable outlook into the very fabric of the build itself.

The key challenge faced by the team was from the constrained site, positioned between an operational building and a busy street. Building the extension, which incorporated a basement and associated groundworks, would prove challenging under normal circumstances, but also faced the additional challenge of being built during the pandemic.

While the work could have feasibly been delivered using a traditional steel frame, a modular approach was taken to effectively tackle the site constraints and crucially reduce the amount of time and people on site. The modular elements were produced offsite, with a large portion of the work being carried out before being delivered and installed on site, as opposed to a longer build programme that a traditional steel structure would have required.

The new build extension was directly built and linked into the existing maternity building at the Leicester Royal Infirmary. It was essential that patients requiring access to the Kensington Building and its associated departments were not impacted on by the capital works being undertaken.

This offsite approach ensured minimal disruption to the wider live site through a shorter build time, along with the need for less labourers on site and fewer deliveries. To aid this further, our project management team selected specific building methods and design elements that ensured a quick yet high-quality finish, while ensuring negligible risk to patient access and adherence to social distancing guidelines in force at the time.

One such design element was the use of brick slips over traditional brick on the modular extension. This simple change reduced the number of deliveries and therefore people to site, but also reduced potential wastage and promoted use of a more efficient process and more sustainable material.

With the modular new-build extension and subsequent phases finished, the new East Midlands Congenital Heart Centre now has a state-of-the-art city centre home, complete with the high-tech equipment and facilities needed to give children born with congenital heart defects the best start in life.

Healthcare

We have worked with more than 50 NHS trusts, charities and private organisations providing healthcare services on the full range of projects.